How Is a Shingle Made? A Behind-the-Scenes Look at What’s Protecting Your Home

How Is a Shingle Made? A Behind-the-Scenes Look at What’s Protecting Your Home

When we think about our roof, we usually picture those familiar asphalt shingles — layered across the surface, keeping out the elements. But have you ever wondered what goes into making a shingle?

Understanding how shingles are made helps explain why they age, why they fail, and most importantly, how products like Fresh Roof can extend their life.

Let’s take a closer look at the process behind the everyday asphalt shingle.

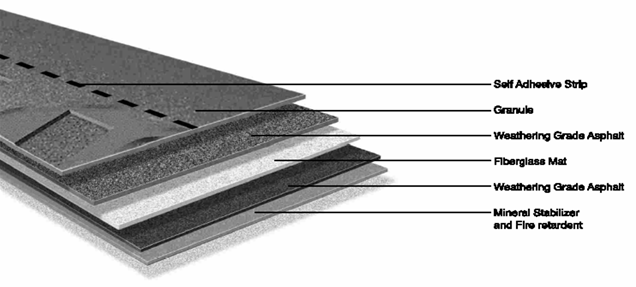

Step 1: The Base Mat — The Foundation of Every Shingle

Every shingle starts with a base mat, which acts as the structural core. This mat is typically made of fiberglass (today’s industry standard) or, in older shingles, organic felt (which is now largely phased out).

- Fiberglass mats are lightweight, fire-resistant, and durable.

- The mat provides the strength needed to hold the asphalt and granules together.

Step 2: Saturation with Asphalt

Next, the mat is coated with asphalt — a sticky, black, petroleum-based material. This is the heart of the shingle and what gives it its waterproofing properties.

The asphalt is oxidized (air-blown) to make it more durable, then applied to both sides of the mat to fully saturate it.

Step 3: Adding Mineral Fillers

To make the asphalt stronger and more stable, manufacturers mix in mineral fillers like limestone dust. These help the shingle resist heat, UV rays, and cracking over time.

This blend becomes what’s known as asphalt coating compound — the thick, weatherproof layer that protects your home from rain, wind, and snow.

Step 4: Surfacing with Granules

On the top side of the shingle, ceramic-coated mineral granules are embedded into the hot asphalt coating. These granules:

- Add color and aesthetic appeal

- Provide UV protection

- Improve fire resistance

- Help with traction during installation

Sometimes, manufacturers even use algae-resistant granules to help prevent streaking and discoloration.

Step 5: Backdusting and Cooling

To prevent the shingles from sticking together during storage, the back side is treated with a release agent like fine sand or talc.

The shingle sheet then moves through cooling rollers to set the shape and harden the material.

Step 6: Cutting and Packaging

Finally, the cooled sheet is cut into individual shingles — typically in three-tab or architectural styles. They’re stacked, packaged, and shipped out to roofing suppliers and contractors.

Why This Matters — And How Fresh Roof Helps

Now that you know what goes into a shingle, it’s easy to see why they dry out and crack over time.

- The asphalt loses its natural oils.

- The granules begin to loosen and wash away.

- The shingle becomes brittle, less flexible, and prone to failure.

That’s where Fresh Roof comes in.

Our patented GreenSoy™ Technology is designed to penetrate deep into the asphalt layer, restoring lost oils, reviving flexibility, and locking in granules — helping shingles perform like new without the cost of replacement.

Final Thoughts

Shingles are a powerful combination of engineering and materials science, but like anything, they wear out over time. Knowing how they’re made helps homeowners understand why maintenance and rejuvenation matter — and why Fresh Roof is the smart choice for extending the life of your roof.

Best Roof Rejuvenation in California: Why Smart Homeowners Are Choosing Restoration Over Replacement